Is the installation of adhesive transparent led film curtain walls difficult?

The installation of adhesive transparent led film curtain walls is not as structurally intensive as traditional LED screens, but it does require specific construction techniques, material compatibility, and environmental conditions. Since the product is based on transparent PET substrate and is ultra-thin, it can be directly adhered to the glass surface, eliminating the need for heavy steel support structures. This reduces modifications to the building's original framework and simplifies future main-tenance.

During installation, the glass curtain wall's material and surface flatness must be evaluated to ensure cleanliness, absence of dust, and no significant protrusions or damage. The attachment method primarily relies on specialized optical adhesive or electrostatic adsorption technology, demanding high glass cleanliness. Pre-installation cleaning of the curtain wall is typically required, and work should be conducted in a temperature-controlled, dry environment to ensure long-lasting adhesion.

The process also involves concealed wiring for signal and power cables, which can be challenging depending on the curtain wall's original structure. Since the adhesive transparent led film itself does not emit significant light, the driving and control modules are usually installed in the curtain wall’s frame or ceiling area. The construction team must plan the wiring path in advance to maintain a clean visual appearance while ensuring proper power and control functionality.

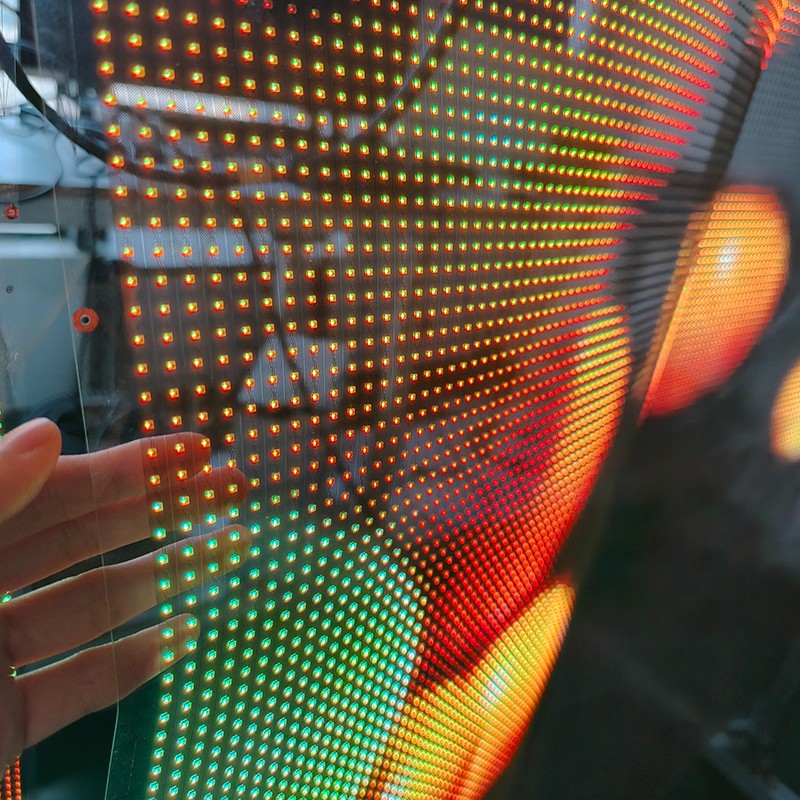

On-site installation requires skilled technicians to avoid air bubbles, wrinkles, or detachment during application. Some adhesive transparent led film models allow for partial module replacement, simplifying maintenance but demanding higher pre-cision during ini-tial installation. The construction team must carefully follow processes such as layout positioning, segmented adhesion, and edge sealing to ensure dimensional accuracy and proper fit.

Regarding environmental adaptability, glass curtain walls are subject to sunlight exp-osure, temperature fluctuations, and wind pressure, requiring meticulous sealing, moisture-proofing, and fastener installation at the screen edges. In some projects, the impact of glass expansion and contraction on the film material must also be considered to prevent long-term peeling or edge lifting.

From a technical workflow perspective, installing adhesive transparent led film involves fewer structural steps compared to traditional cabinet screens but requires greater attention to detail. This is especially true for high-rise curtain walls, curved glass, and large-scale applications, where proper design and professional execution are crucial. By addressing these technical considerations during project planning and construction, stable installation and optimal visual effects can be achieved.